- Mainpage

- Directory

- Titan

- Titanium, titanium products

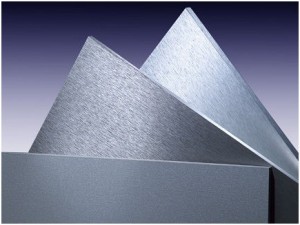

Titan sheet

Dignity

Namagnichennosti, heat resistance, resistance to wet corrosion and contact with aggressive chemicals, resistance to deformation, low thermal conductivity, satisfactory workability, good ductility and weldability. These and other advantages bring him to the fore of modern technologies, technology and science. Titanium sheet is able to endure great exposure to soil, atmospheric moisture and fatigue loads. It is used in the condition of cryogenic cooling. At interaction with atmospheric gases and its surface is covered with a durable protective oxide nitride film. In the food industry and in medicine it is used due to biological inertness, and high heat resistance, specific strength, corrosion resistance make it the main in the environment of structural materials.

Disadvantages

Almost the only disadvantage is the high cost. Because of its exceptional properties of titanium require a lot of effort in production. However, despite its high cost, this metal is in high demand in modern industry.

Use

Without the titanium sheet is difficult to imagine modern gas production, petrochemical industry and processing plants. Mark V. T. is used in the production of parts that operate at temperatures up to +450°C. They are indispensable in the chemical industry, rocket production, shipbuilding, aviation, engineering. Brand VT6 has a high specific strength and corrosion resistance, heat resistance (up to +450°C) and namagnichennosti. Such properties provide advantages in the engineering and aviation industry — in the manufacture of airframe, power set, chassis, fasteners, tools pylons, wing, engine parts, hydraulic cylinders, and in rocket (fastenings, plating). From alloy VT6 in shipbuilding, thanks to its durability in sea water to produce propellers, trim, heat exchangers. Titanium sheet series used in the Navy, aviation, chemical industry, mechanical engineering. The surface must be absolutely perfect — no hollows, roughnesses, cracks. A sheet of stamps FROM a-4 with additives of magnesium and aluminium stand for 2000 h temperature +350°C. It relates to wrought alloys. Stamping is performed in cold condition.

Welding

It is easy to weld electron-beam, argon-arc and contact method.

Marking

Domestic alloys are labeled as follows: first letter — the firm-the developer. The letters V. T. means «VIAM"-Titanium, and FROM experienced Titan, which was developed metallurgical production Association of Verhnesaldinsky — VSMPO in cooperation with VIAM. Leaves improved flatness are indicated; and normal flatness — additional markings are not. High quality finishes is denoted by — P and high — V. Normal trim does not have additional designations.

| Thickness | Cutting | Ed. measurement | Price. |

|---|---|---|---|

| Sheet VT1−0 | |||

| 1 mm | 800x2000 mm 700x2000 mm 1000x2000 mm | kg | contract. |

| 2 mm | 950x1830 mm, 950x1760 mm, 950x1880 mm, 960x1285 mm, 950x1915 mm | kg | — «- |

| 1.5 mm | 1000x2000 mm | kg | — «- |

| 3 mm | 425x1480 mm, 380x1220 mm | kg | — «- |

| 3 mm | 1000x2000 mm, 950x2270 mm, 1000x2210 mm 1030x2470 mm 1040x2520 mm, 1020x2490 mm 1050x2000 mm, 1050x2500 mm 1050x2220 mm 1070x2480 mm 1090x2335 mm 1070x2520 mm | kg | — «- |

| 3 mm | 430x1360 mm | kg | — «- |

| 4 mm | 1000x2000 mm | kg | — «- |

| 4 mm | 450x1240 mm | kg | — «- |

| 5 mm | 1000x2000 mm | kg | — «- |

| 6 mm | 1000x2000 mm | kg | — «- |

| The VT20 sheet | |||

| 2.5 mm | 600x2000 mm | kg | — «- |

| Sheet OT4 | |||

| 0.8 mm | 600x2000 mm | kg | — «- |

Manufacturer

The sheets VT1−00, VT1−0 with a thickness of 2 mm are manufactured in length up to 2 m In length from 1 to 5 m thickness up to 10.5 mm. are Manufactured in annealed form, after which prokleivayutsya can be fixed and cut at a 90° angle. The edge of the sheet should not have rough burrs. The surface may not have delamination and cracks, tears and depressions, scale, and needs to be etched. Z agotovki of alloys VT-6S, W-20 and VT5−1 with a thickness of 6 to 10,5 mm are produced with the possibility of further patterns without fine trimming. Chem. part of the rent is normalized to GOST 19807−74, 90013−81 OST 1. The selection and preparation of samples for determining the chemical composition of standardized GOST 24231−80.

| Form of delivery | Long | Diameter | Width | Thickness | |

|---|---|---|---|---|---|

| Titan sheet | 700−2000 mm | 700−1000 | 0.3−15 | ||

| Titan round | 500−5000mm | 12-φ300 mm | |||

| Titanium wire | 0.5−6 mm |

| Form of delivery | Length, mm | Wall, mm | Outer diameter | Note |

|---|---|---|---|---|

| Titanium pipe | 1000−5000 | 0.3−10 | 2−90 mm | Weight of one pipe must not превышать200 kg |

Storage

Stored in covered warehouses in certain temperature conditions, where there is adequate protection against various mechanical and other damage.

Buy at best price

The company «AVEK global» specializiruetsya on the sale of any metal alloys. We offer products from warehouses in Russia and Ukraine with delivery to any region of the CIS and abroad. Our experts will pack, complement and promarker your purchase, and controlled delivery at the specified address. All products are certified and available. The price depends on order volume and additional conditions. Deliveries are made promptly. When wholesale purchases are offered preferential discounts.