- Mainpage

- Directory

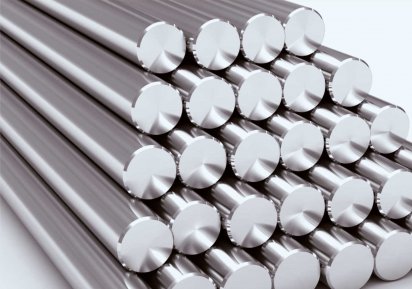

Alloy steel

Relevance

Alloyed alloys have special additives: tungsten, vanadium, chromium, molybdenum, nickel, silicon, manganese, which give the material the most valuable qualities. The use of special additives increases strength, wear resistance, heat resistance.

Characteristic

Ligatures have a multifaceted effect on the quality of steel. Chromium increases hardness, prevents rusting; Nickel gives plasticity; Tungsten increases hardness, redness; Vanadium increases strength, resistance to impact, erasure; Cobalt increases heat resistance, magneto-permeability; Molybdenum increases the reddensitivity, strength, counteraction to oxidation at high temperatures. The proportion of manganese above 1% increases hardness, resistance to shock loads, wear resistance; Titanium increases stability, corrosion resistance; Aluminum increases scale resistance; Niobium — acid resistance; Copper gives the alloy plasticity, prevents rust. Particularly high-quality steel besides the above-mentioned components contains boron, zirconium, selenium, nitrogen.

Categories

Quality steel containing several ligatures can be divided into 3 categories according to their design: 1) structural, 2) instrumental, 3) high-quality with special physical and chemical properties. Saturation by alloying components gives off low-alloy steel — less than 3% of alloying additives; Medium-alloyed — 3−10%; High-alloy — above 10%.

Marking

The first numbers of the mark reflect the carbon fraction in one-hundredths of a percent. For example, 10 means 0.10%. When the numbers are initially absent, the carbon fraction is more than 1%. Next comes the letter abbreviation. If there is no digit behind the letter, then this element is less than 1%. The letter «A» means the minimum content of harmful sulfur, phosphorus. For example, the 12Х2Н4А alloy contains carbon up to 0.12%, chromium up to 2%, nickel up to 4%. Alloy G13 — contains not less than 1% carbon, 13% manganese. Structural alloy steel in accordance with GOST 4543−71 is divided into 3 categories: high-quality, high-quality and the highest quality. The first is designated by the letter «A», the highest quality — the letter «Ш» through the dash. For example, 12ХНЗА — quality, З0ГС-Ш — the most qualitative. High-quality steel has an acceptable sulfur percentage up to 0.025%, high-quality steel up to 0.015%.

Using

The most demanded are chromium steels. They differ in hardness, stability, corrosion resistance, relatively inexpensive. Widely used as a structural material for the production of weapons. Manganese alloys, for example, 15 G, 20 G, 40 G, 45 G 2, are characterized by wear resistance. Extraordinarily high-quality grade G13, which is used for caterpillars of tractors or tanks, is unusually durable. Siliceous, chromium-silicon steel possesses exceptional firmness, elasticity. Nickel — increased plasticity, the highest electrical resistance, along with exceptionally solid tungsten alloys. The latter are indispensable for instrumental processing of metals, impact-pivot drilling. Titanium gives lightness, corrosion resistance, it is a non-alternative material for underwater shipbuilding and supersonic aircraft.

Buy at a bargain price

By purchasing the alloy you need through the company Avek Global, you can be completely confident in the quality of the product and the objectivity of the price scale. The cost is formed taking into account the technological features of production without including additional costs. We offer excellent purchasing conditions for retail customers, as well as large-scale productions. All products are certified. You can get acquainted with the catalog, see our price list and get the necessary information through the website of avglob.org. Our consultants are always ready to answer the current questions. Time for the implementation of orders — the most minimal. Discounts are given to wholesale buyers.