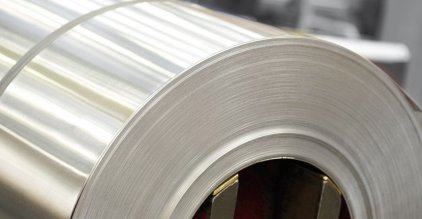

Sheet, strip 40x13 - 1.4034 - aisi 420

Composition

40X13 steel — stainless steel is heat-resistant iron-based alloy of the martensitic class. Smelted in an open electric arc furnace. Includes chrome 12−14%, Ni — 0.6%, manganese and silicon at 0.6%, carbon — 0,26−0,35%, a few thousandths of a percent of sulfur and phosphorus. The analogue — alloy 30X13.

Procentnyy part of the brand 40H13 (GOST 5632−72)

| Steel | Si | C | Mn | P | Cr | Ni | S | Fe | |

|---|---|---|---|---|---|---|---|---|---|

| 40X13 | ≤0,6 | 0,35−0,44 | ≤0,6 | ≤0,03 | 12−14 | ≤0,6 | ≤0,025 | The rest |

Manufacturer

The brand 40H13 sheet is hot-rolled and cold-rolled method. Hot-rolled thick plate (4−160 mm) is made according to the following GOST: 19903−74 and 1577−93. Thin sheets (0.5 to 3.9 mm) is manufactured in accordance with GOST 16523−89 and 19903−74 and are supplied heat treated, the surface can be netravlenoy and etched. Standard width 710−1800 mm,

Use

Sheet and strip brand 40H13 have the widest range of applications in the flat spring, parts of high temperature installations that are operated in mechanical engineering and petrochemical industries in a slightly aggressive environments at temperatures up to 450 °C. Flat steel products brand 40H13 in demand in the gas industry, power engineering, for production of components of steam generators, pumps, cracking plants. This steel is widely used in medical and food industry, in shipbuilding and in the creation of architectural decorative elements. For the production of medical instruments used quenching at t° 1040 °C.

Buy at best price

Large assortment of rolled steel 40X13 in stock LLC «AVEK global» can satisfy any consumer. The quality of the finished product is ensured absolute compliance with all technological norms of production. The order execution time is the shortest. If you have any questions you will receive detailed advice from experienced managers. In the implementation of wholesale orders the company provides flexible system of discounts.