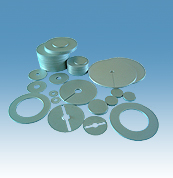

Molybdenum disc

The advantage of molybdenum disc

The advantages of molybdenum disks applies mechanical strength, exceptional corrosion and chemical resistance to most aggressive reagents, refractoriness, low thermal coefficient of linear expansion, high modulus of elasticity, all these qualities make discs of molybdenum is indispensable in the most difficult conditions of production. Molybdenum discs compared with tungsten easier almost doubled, so molybdenum products have high specific strength (at a temperature of not more than 1370 °C).

| Physical quality | |

|---|---|

| The temperature at which the obtained data the features of t°C | 20°C |

| The linear thermal expansion coefficient α [1/°C] | Of 4.9x10-6 |

| Density [g/cm3] | 10,2 |

| The melting temperature t°C | 2620°C |

| Specific heat at 20 °C [kJ/(kg·deg)] | 0,256 |

| The thermal conductivity K [W/(m·K)] | 142 |

| Electrical resistivity R, Mhmm2/m | 0,054 |

Chemical properties

Molybdenum reacts with hydrochloric, sulfuric acids only at the temperature. 80−100°C. Nitric acid, Aqua Regia dissolved molybdenum only when температуре100°C. In cold alkaline solutions it is stable, but in hot alkaline solutions the molybdenum slowly being destroyed. Impurities of carbon, oxygen, silicon, aluminum, nitrogen, iron, sulfur and calcium, phosphorus, contained in the technical molybdenum in hundredths or thousandth fractions of a percent, significantly affect the properties of molybdenum. The bulk of these impurities makes molybdenum more fragile. Most harmful of all impurities is oxygen. If it is contained in a volume 0,0008−0,004%, the low-melting oxides can lead to a sharp increase in its brittleness and a decrease in properties to plastic deformation, especially in the simultaneous presence of carbon with nitrogen. With increasing percentage of oxygen than 0.015% molybdenum is not handled the pressure and becomes brittle.

Disadvantages

Practically the only disadvantage is the high cost of molybdenum disks, since Mo is a metal belonging to rare earth elements and in its pure form is quite difficult to identify. Besides, he is refractory and hard to work.

Production

The drives are manufactured by sintering, cutting or machining. Configuration, and tolerances and dimensions agreed with the customer. Technology for the production of discs, as well as the characteristics of the material ensure high reliability and temperature resistance. The cost is determined by the size, complexity configuration and additional requirements of the customer.

Application

Molybdenum discs are used as structural elements in silicon power semiconductor devices.

Buy at best price

A huge range of molybdenum disks in stock LLC «AVEK global» can satisfy any customer. Absolute compliance with all technological norms of production ensures the quality of the finished product. Deadlines all orders the shortest possible. For any questions, experienced managers will give a full detailed advice. Carrying out wholesale orders, you can count on company-provided flexible system of discounts.